Self-leveling epoxy flooring is a high-performance flooring system known for its smooth, seamless, and durable finish. It features a liquid-rich epoxy formulation that, when poured, spreads evenly to create a flat, level surface that fills in cracks, holes, and other imperfections on the substrate. This self-leveling property makes it ideal for areas requiring an aesthetic and uniform appearance along with high durability. Key benefits of self-leveling epoxy flooring include: Seamless application with no joints or seams, reducing places for dirt and bacteria to accumulate, thus enhancing cleanliness and hygiene. High strength and durability, capable of withstanding heavy foot traffic, forklifts, and industrial machinery. Slip-resistant properties, ensuring safety even on its glossy surface, suitable for environments prone to wet conditions. Easy to clean and maintain with simple soap and water, making it perfect for industries such as food production, pharmaceuticals, and healthcare. Aesthetic versatility, offering various colors and finishes including metallic and solid tones to improve the visual appeal of spaces. Its thickness typically ranges from 1 mm to 5 mm, allowing it to cover uneven floors and deliver a professional finish. Self-leveling epoxy floors are commonly used in commercial, industrial, and residential settings, particularly in warehouses, labs, hospitals, showrooms, and clean rooms where a flawless, durable floor is critical. Overall, self-leveling epoxy flooring offers a clean, safe, and attractive surface that combines functionality with style, durability, and ease of maintenance. This makes it a top choice for spaces requiring impeccable floor quality and appearance.

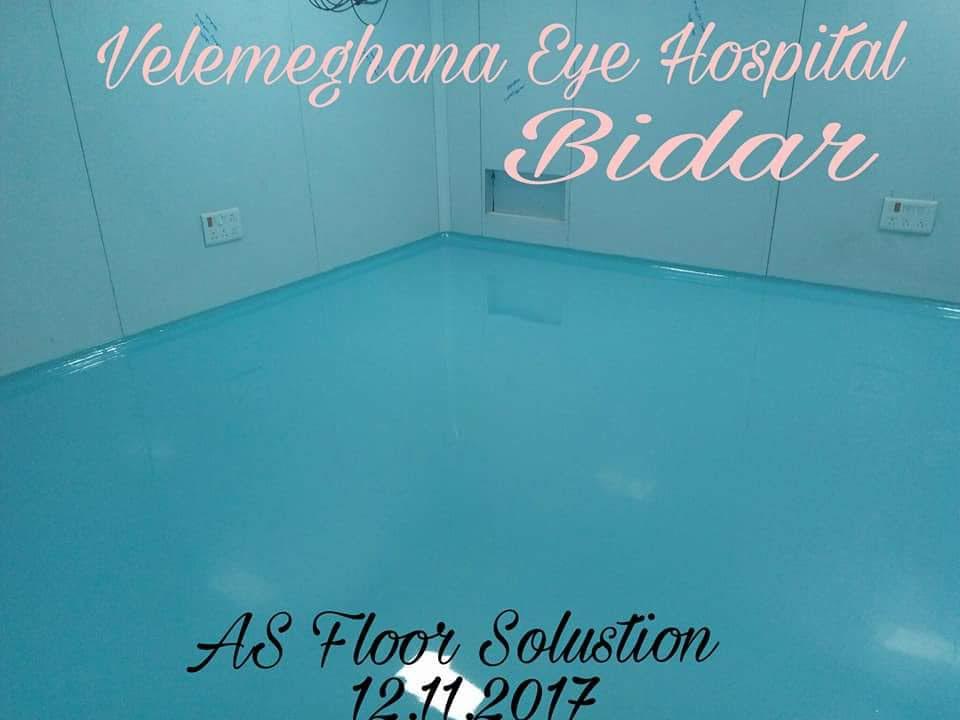

About AS Floor Solutions

The Best Flooring Contractor in hyderabad

Products

Featured ProductsWhat We Do

Have any custom requirements?

Latest Updates

Read Our Latest Updates & News

×

![]()